Know about all the types of MDF boards and MDF sheets and their usage

One of the most used building materials in defining the interiors and exteriors of our homes is WOOD. There are different types of woods harvested from forests across the globe, each having their own set of benefits and demerits of usage. But before you feel perplexed about this science of wood and wooden materials, we will be explaining you all about this most commonly used, durable MDF wooden board.

Medium-density fiberboard, or MDF, is fabricated from wood scraps like sawdust and shavings, together with resin and wax. It’s a cheap material that, once cut into panels and sanded smooth, may be utilized for many interior decoration projects, from furniture to panelling.

That’s why the team at Woodology takes a hands-on approach to every job. The quality staff inspects their MDF products several times before sending them to the store so that only the best of the best make it to the consumers. We have a varied selection and dimensions of high-quality MDF boards available, and after you choose what you need, we ship them directly and safely to you.

Let us tell you more about the types of MDF boards.

Types of MDF boards

- Composite panels and plywood

Though particleboard and plywood are engineered wood products, they are not medium-density fiberboard (MDF). Particleboard is manufactured by pressing tiny wood chips together with glue and heat; the resulting panels are then cooled, flattened, and coated with resin to make them water-resistant. Particleboard is much cheaper than MDF, but it isn’t as sturdy, isn’t as resistant to dampness, and may warp easily.

- Common Medium-Density Fiberboard

Standard MDF comes in huge sheets that may be both heavy and rigid. A typical MDF panel is significantly heavier than plywood, so you’ll need at least two people to move it, and it’s also easy to scratch and crack around the edges. Tan and dark brown variations are the most prevalent, and they may be purchased in a range of thicknesses from 1/2 to 3/4 inches.

- Low-Weight, Medium-Density Fiberboard

MDF’s weight might be an issue in certain situations, a lighter variant called ultra-light MDF is also available. Due to their lower density, these often weigh around 30 per cent less than conventional MDF.

- Insulated, fireproof MDF

These panels, classified as fire-rated MDF, may be identified by either a red or blue label. Some building rules mandate using only Class-1 certified wood, which is why these products are designed to reduce the pace at which fire spreads. Even if they aren’t required by law, they are an intelligent choice for locations prone to wildfires or any application within three feet of a heat source, such as cabinets installed next to a range or oven.

- MDF that won’t warp or swell when exposed to moisture

In the same way that the presence of blue or red markings on an MDF panel may indicate the panel’s fire resistance, green markings indicate the panel’s moisture resistance, making it appropriate for use in wet areas like kitchens and bathrooms. Remember that water-resistant is not the same as waterproof, so these items may still be harmed by prolonged exposure to moisture, and keep them confined to the inside if possible.

Usage and qualities of MDF boards

- Used in the Fabrication of Low-Cost Furnishings

Bookshelves, entertainment centres, and other low-priced furniture are often made from MDF boards. Pre-assembled furniture is another common usage for it. Since MDF is cheap and straightforward to manufacture, it helps reduce furniture costs.

- The ability to be moved about with ease

For items that will need to be moved often, lightweight MDF boards are utilized instead of ordinary MDF boards. Mobile homes, convention booths, stage sets, etc., fall under this category.

- To be used in the construction of cabinets

Cabinets for the kitchen and the bathroom, bookcases, and display cabinets, are often constructed from MDF board. MDF cabinets may be given a wood grain texture and look with wood laminates.

- Flexibility

MDF boards are so flexible that they can be shaped into almost any curve or bend. The usage of such MDF boards is expected in constructing items needing considerable curves or slopes.

- Fireproof

The qualities of these materials include being fireproof. Because of this, MDF boards are often utilized in constructing commercial structures like offices and stores that must adhere to specific safety regulations. Fireproof MDF boards are utilized in residential buildings as well.

- Moisture-resistant

MDF boards are constructed with a unique resin that makes them impervious to water. Flooring, furniture, and other items utilized in moist settings like kitchens and bathrooms are often crafted using MDF boards. In addition to their usage as insulation, they may also be used as vapour barriers.

- Excellent for exterior usage

MDF is also a backing for roof shingles since it is a good material. Wood, phenolic resins, zinc borate, and a water-repellant make MDF panels ideal for outdoor use. These MDF boards are formaldehyde- and urea-free. Doors, signs, and other exterior fixtures are constructed with them because of their durability and resistance to moisture, rot, and termites.

- Can protect sound

MDF has the capability to insulate against noise because of its construction. This is why it is utilized for soundproofing floor underlayment, media room walls, and building construction.

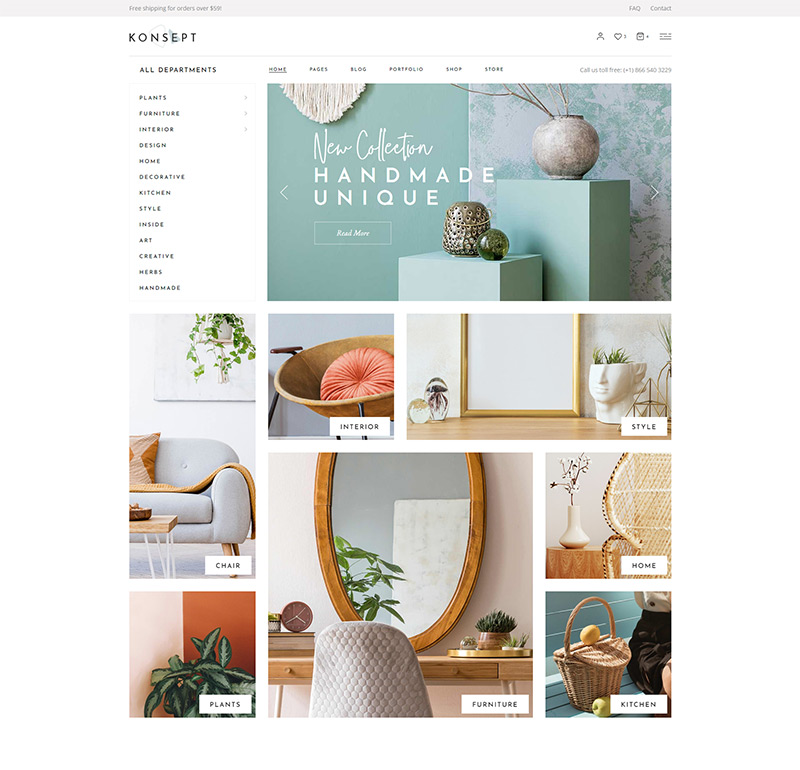

Used in constructing shelf panels, are the MDF boards on the backs of shelves in shops.

Leave a Reply